- Mazak FH 5800 machine work envelope x27.95, y24.02, z25.98

80 atc ,equipped 12k rpm 30 hp spindle, 2 - 1 deg indexing pallet tables, fusion 640m controls, mp10 Renishaw probe

630.679.9571 | info@contournconcepts.com

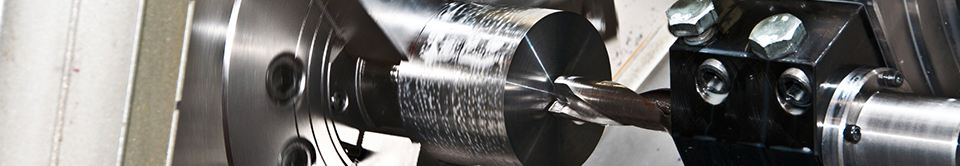

Contour N Concepts Inc. utilizes top of the line machining and manufacturing equipment in all of our production processes. Our 6000 square foot facility currently houses multiple Mazak CNC machines , ranging from CNC Horizontal and Vertical milling to CNC turning centers.

Our Horizontal Machining Center holds high accuracy and reliability that allow us to produce precision machined parts with roughly a 30'' inch cube work envelope. With the compliment of a 12k rpm spindle, multiple 1 degree indexing tables and a Renishaw MP10 probe we can handle any challenge given to us.

The CNC Vertical Machining Centers accommodate all of the daily tasks from complex prototype and low volume parts to production machining. With machine axis travels up to 40.00'' inches and the versatility of efficient programming, our experience machinists can perform multiple piece part machining at a rapid rate and competitive cost.

Our CNC Turning cell consists of multiple Mazak lathes with chuck sizes raging from 8'' to 12''inches with up to 3.00'' inch bar capacity. We can handle turning parts up to 19.00 inches in diameter and 40.00 inches in length. With live tooling features we can also be competitive with complex parts.

Our other internal services can offer unmatched results from manual machining and turning to our welding and assembly, we can accommodate all your needs with one stop.

80 atc ,equipped 12k rpm 30 hp spindle, 2 - 1 deg indexing pallet tables, fusion 640m controls, mp10 Renishaw probe

(capable of height measurement , internal and external diameters , displacement between surfaces , bores , external cylindrical , and arbitrary shapes)

Contour N Concepts utilizes only the highest quality sources for the supply of secondary operations such as grinding, broaching, heat treating, gear cutting, plating, anodizing and other coatings, and all others in accordance with the requirements of our customers.

All secondary operations suppliers are located in the greater Chicago area in close proximity to our manufacturing plant.

Contour N Concepts, Inc. offers custom precision machined parts and serves various industries ranging from: food , chemical , printing, energy , extrusion and other OEM markets.

We serve customers in many locations, but our main concentration is in Illinois.